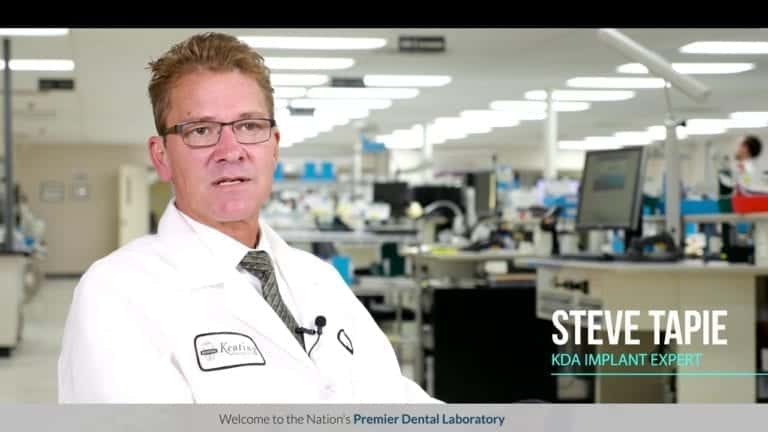

Rolling into the Keating Dental Lab custom abutment department on this insanely windy and cold California Monday morning is always a treat, that is since the most qualified individual probably on the planet is at the “implant helm” man-ning the metaphorical CAD/CAM fleet where the Nobel Procera scanners dwell. I know this area pretty well by now since we have filmed a few things in this part of the KDA lab. Walking up, Steve is hard at work as per usual and on the phone with the clinician, which is pretty much how I find him every time I am down here. Since I am never in a hurry, I let him do his normal consulting with the clinicians on their custom implant cases. I never mind waiting when someone is lending a helping hand. Steve spends a good part of his day making sure the clinicians that are sending the implant abutment cases to the lab have the maximum amount of communication on these intricate matters.

After a brief chat with Mr. Tapie and a Talent Release from, we get to chatting about these dental implants and custom abutments we are about to interview on. I like to have an idea of what I am filming before hand and do my research well, but the theory behind implants and the ever growing technological advances in the industry make it difficult for me to get a good lead on what’s really going on. This is where Steve really enlightened me on the subject especially because will be the recipient of 2 of them this Xmas.

“We partner with 12 major implant companies, including Nobel Biocare®, Straumann®, Atlantis, Biomet 3i® and Zimmer. Keating’s abutment laboratory also can work with any manufacturer you need even smaller company’s that most labs won’t touch. Because KDA partners with top manufacturers to fabricate genuine custom implant abutments rather than producing them in house like many labs do, our implant abutments are protected by manufacturers’ warranties, and do not void the warranty of the implant when seated” Steve stated to start off my implant education crash course.

Implant Scan Abutments are designed for intra oral scanning or dental laboratory scanning of models to precisely transmit prosthetic information of the prepared teeth or area and exact implant(s) location. Scan manufacturer abutments remove the necessity for physical impressions although they are still recommended. The implant data is transmitted electronically to the dental lab for fabrication of CAD/CAM custom abutments. Steve and the Keating Lab goes above and beyond to work with these clinicians and partners to insure that the customization is to exact abutment specifications.

“I think we have more of a personal touch with the doctor. A lot of the times the doctor will get a case from the periodontitis or the surgeon, and hears the case and sometimes there’s questions that need to be answered that a laboratory communicating with the doctor or general practitioner can’t answer. The communication, I think, is key to where the end result is going to be the health of the patient and the end quality and product for the patient and the doctor. Like we all know, the patient is the walking billboard for that practice, which is in turn, that practice is a walking billboard for us and the implant restorations that we do here.