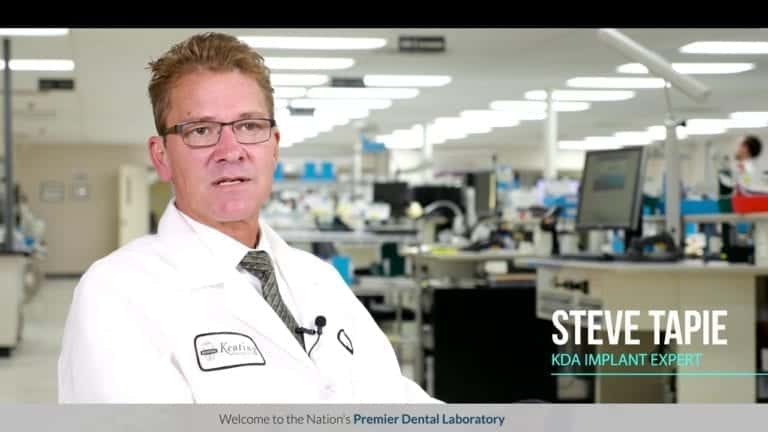

November 16, 2015 — Nothing makes Monday’s more bearable than being able to visit your favorite dental implant expert, especially when you’re about to have 2 of those bad boys put in. One of the most intricate and innovative subjects I have come across in a long time is dental implants and implant abutments. Really, until you can grasp the whole theory behind them it’s easy to get lost in all the manufacturer names, scanners, and variations in which the abutments are made. Good thing my buddy Steve T. always keeps his door open to a fellow “human missing posterior teeth”.

The Evolution of CAD/CAM Custom Abutments in Dentistry

In the realm of dental restorations, the advent of CAD/CAM technology has marked a significant milestone. Custom abutment fabrication, once a manual and time-consuming process, has been transformed into a highly precise and efficient practice, thanks to CAD/CAM technology. At Keating Dental Lab, a leading digital dental lab, the adoption of tools like the Nobel Procera scanners has enabled the creation of CAD/CAM custom abutments tailored to individual patient needs. This allows for more accurate, better-fitting implants that greatly improve patient outcomes.

Rolling into the Keating Dental Lab custom abutment department on this insanely windy and cold California Monday morning is always a treat, that is since the most qualified individual probably on the planet is at the “implant helm” man-ning the metaphorical CAD/CAM fleet where the Nobel Procera scanners dwell. I know this area pretty well by now since we have filmed a few things in this part of the KDA lab.

The Role of Nobel Procera Scanners in Revolutionizing Dental Labs

The Nobel Procera Scanner stands out among the technological advancements in dental labs. Its precision in scanning allows for unparalleled accuracy in creating implant abutments, making it indispensable in the workflow of modern digital dental labs like Keating Dental Lab. This technology not only streamlines the creation process but also ensures that each custom abutment fits perfectly with the unique contours of a patient’s dental structure.

Walking up, Steve is hard at work as per usual and on the phone with the clinician, which is pretty much how I find him every time I am down here. Since I am never in a hurry, I let him do his normal consulting with the clinicians on their custom implant cases. I never mind waiting when someone is lending a helping hand. Steve spends a good part of his day making sure the clinicians that are sending the implant abutment cases to the lab have the maximum amount of communication on these intricate matters.

Partnering with Leading Manufacturers for Quality Assured CAD/CAM Abutments

“We partner with 12 major implant companies, including Nobel Biocare®, Straumann®, Atlantis, Biomet 3i®, and Zimmer. Keating’s abutment laboratory also can work with any manufacturer you need even smaller companies that most labs won’t touch. Because KDA partners with top manufacturers to fabricate genuine custom implant abutments rather than producing them in-house like many labs do, our implant abutments are protected by manufacturers’ warranties, and do not void the warranty of the implant when seated,” Steve stated to start off my implant education crash course.

This critical partnership ensures that Keating Dental Lab remains at the forefront of implant dentistry, providing clinicians and patients with high-quality, durable solutions that stand the test of time.

You may also want to watch: Using CAD/CAM Technology For Dental Restorations

Opting for Digital Dental Lab Scanning: A Leap into Modern Dentistry

Implant Scan Abutments are designed for intraoral scanning or dental laboratory scanning of models to precisely transmit prosthetic information of the prepared teeth or area and exact implant(s) location. Scan manufacturer abutments remove the necessity for physical impressions, although they are still recommended. The implant data is transmitted electronically to the dental lab for fabrication of CAD/CAM custom abutments. Steve and the Keating Lab go above and beyond to work with these clinicians and partners to ensure that the customization is to exact abutment specifications.

The transition from physical to digital impressions marks a significant leap into the age of modern dentistry. Digital lab scanning not only enhances efficiency but also significantly reduces the margin of error, leading to an overall improvement in the customization and fit of dental implants.

You may also want to watch: Using CAD/CAM Technology For Dental Restorations

“All Hands On Deck,” says Steve, highlighting the importance of a personal touch and effective communication in crafting perfect dental implant restorations. This collaborative approach between the lab, doctors, and patients is what sets Keating Dental Lab apart, ensuring each dental implant is not just a product but a bespoke solution crafted with expertise and care.

Despite my casual musings about “DIY implants,” the rigorous process, from bone grafts to precise abutment fitting, demands professional expertise. This reinforces the critical role of experienced dental professionals and advanced labs in ensuring optimal outcomes for dental implants.

Keating Dental Lab, as a full-service digital dental lab, embodies the fusion of art and science in dental restoration. Whether it’s guiding a patient through the process of getting dental implants or showcasing advanced lab techniques like How to Take A Prep Shade on Anterior Crown Restoration, the dedication to advancing dental practices through technology and expertise shines through.

In conclusion, the exploration of CAD/CAM custom abutments, the technological prowess of Nobel Procera scanners, and the collaborative approach of California dental labs like Keating Dental Lab in creating removables and implant restorations underscore the transformation in dental restoration practices. This evolution not only promises more accurate and aesthetically pleasing outcomes but also a future where dental restorations are more accessible and comfortable for patients worldwide.

Thanks again to Steve Tapie for doing this amazing interview and the Keating Dental Lab Team for keeping the noise down in the lab (apparently NOT a reasonable request at 10am in a dental lab)!

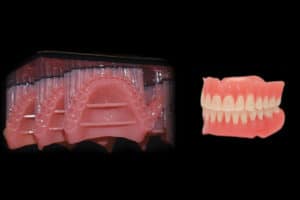

Keep your eyes on the horizon for the next interview when I go undercover as a Ivoclar denture tooth to get a glimpse into the Denture Lab and Removable department.

Timothy Patrick

Creative Director/DP

Full 4K Video Transcript:

Here at Keating Dental Lab we also have our custom design abutments, whether it be from our Atlantis or our Noble. We also design them here with a Straumann and we send them out to Noble Biomet for the 3i encode and or abutments. We can utilize all these different scanners depending on what the clinician would like to use. The Atlantis Abutments we actually scan, design the picture here, we put the flows on, and we sent them out to Atlantis to the file to Atlantis to have the abutment fabricated. We have to approve every single design before it is mailed out.

We have a great designer here, Bernie Rico, he will design them, he will alter them, modify them slightly. We sometimes get together and we overview some of these cases, and then we do some slight adjustments into the abutment so we get the end result is exactly what we’re looking for. That’s one thing we can use with our Atlantis abutment. Atlantis, of course, has almost every single fixture out there. We also can do the zirconium abutments for Atlantis, and the gold-hue abutments for Atlantis when you want to have the all-ceramic restoration and you have a gold collar, which has a nice show through and a nice tissue contour and color coming through. You can’t go wrong with the Noble, Atlantis, or our Straumann, which we utilize all different systems.

With the Straumann we can design them here, similar to the Atlantis. We can approve the design and they send them. We also [00:06:00] can use the 3i, and of course the endcode, where you just take the impression of the 3i encode, send us the impression of the scanned body of the mapping collar and we send it to them, they place the analog and send the abutment to us. There’s a lot of companies that aren’t well known but absolutely will take care of you. If you send us a case, and I don’t recognize it as a common brand I’ll make a phone call, we’ll look it up, get on the internet, and I’ll make a call to a local rep or rep that you’ve been working with, and we’ll find out what it is. Like I said, there’s so many systems coming out and we have to stay on top of it. I think it’s the communication that we have with the respective clinician and the expectations of the patient, and then we can come together and have a good restoration with a great end result.