Digital Denture Lab

Why are dental labs incorporating digital dentures into their companies? For one, it is a tool that has revolutionized the way people create dentures. The digital denture is produced using technology versus doing everything by hand and tools. The digital denture is made using a 3D scanner to scan the impression of the patient’s mouth and then uploaded into a system designed according to the specifications of the patient’s mouth. When the design is created and approved, it is sent to our 3D printers and fabricated as a base. We then add the teeth from a top manufacturer for a high-quality appearance.

What’s the difference between digital dentures and traditional dentures?

The digital denture is known to be more durable and has a better fit overall. It may lack in appearance that traditional methods would be a better option. However, digital dentures are designed to be mistake-free as the accuracy of 3D printers and dental software make it easy to produce highly functional removable restorations. For more information about the digital denture made at our dental lab.

What’s the difference between 3D Printed and CAD/CAM milled digital dentures?

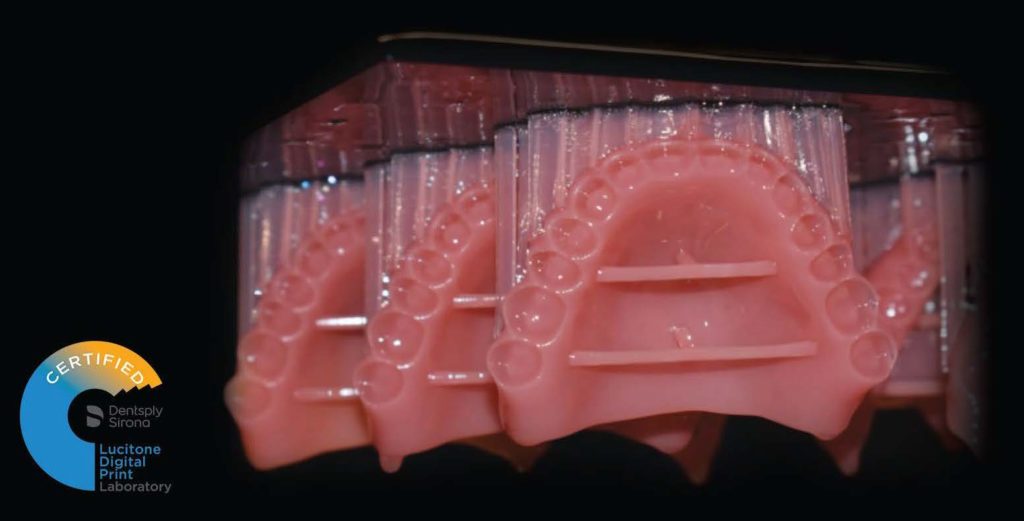

There are several ways to produce digital dentures, such as 3D printed and CAD/CAM milled digital dentures. These production methods are based on the differences in materials and technology used to fabricate the restoration base. For example, a 3D digital denture is developed by first receiving the patient’s impression and then designing the restoration using dental software. The CAD/CAM milled digital denture starts using the same process. However, the 3D digital denture is printed, adding material, and the CAD/CAM milled version reduces material. Let’s get into more detail about how the two techniques differ.

You may also want to watch: Using CAD/CAM Technology For Dental Restorations

Not all 3D Printers are the same

The 3D printers that fabricate digital dentures come in all shapes and sizes but only matter how accurate the microns are for fit and function purposes. For the lab technicians, it is crucial to have a printer that can produce at higher speeds without losing quality. Therefore, we incorporated 3D printers, considered the best in the market for these qualities.

The Lucitone Digital PrintTM Denture Benefits

- Higher patient Satisfaction

- Better Retention and adaptation to anatomy

- Body Activated Material

- Responds to Body temperature to increase strength two-fold

- Permanent Digital Record

- Easily replace a damaged denture

- High Impact with IPN Durability

- Deliver exceptional wear and stain resistance.

Types of liquid resin used

We use an acrylic resin that is extra strong so that the patient can appreciate the longevity of having a denture that won’t wear quickly over time. Again, we use top-of-the-line recommended material for these circumstances. These liquids are formulated with extensive scientific research to be biocompatible and heat-activated when placed orally into the patient’s mouth. Once the material is cured, it becomes solid. This highly trusted method is used to create digital dentures.

Types of teeth and price difference

Our lab uses teeth from top dental manufacturers collaborating with 3D printer companies. Our digital denture is priced the same as our KDL Premium Denture Complete, a highly valued and impressive product that digital dentures have not entirely replaced. The more people learn about the digital denture option, the more they will likely switch over. Our lab uses the highest quality materials, it isn’t easy to choose, so we recommend trying the digital denture. We also have a non-digital denture like the KDL Premium Denture Complete and the KDL Denture Complete, which has more affordable and high-quality teeth. Our Lucitone 3D Digital Print Denture Complete, our digital denture, will include teeth by Dentsply.

The Digital Denture requires fewer steps

Creating traditional dentures usually takes more than a few extra steps when creating the final restoration. Luckily the digital denture made at Keating Dental lab is limited to only four steps defining any room for error. We can create a digital denture in the lab in only seven days. The clinician will also have fewer visits with the patient as we make a free try-in denture so that the patient is confident in their decision and sees the outcome. Everything is FDA-approved, so there is no worry about health concerns. Checking for bite registration and occlusion will be a breeze.

The Biofunctional Prosthetic System

Another step included in the process of digital dentures is the use of a centric tray. The use of a centric tray captures the occlusion. When this method is applied, there are fewer adjustments.

They can be reused, save time, and work perfectly to determine centric relation for complete dentures. Please watch the video with Dr. Frank Lauciello describing the centric tray.

Conclusion

The choice of digital denture workflows varies from lab to lab. Some 3D printers are better than others based on the accuracy of fit. Our lab offers CAD/CAM milled restorations, 3D printed dentures and injected mold techniques. There are pros and cons to digital workflows, and we believe our methods are adequate in presenting high-quality, fully functional denture restorations.

Recommended Reading – Digital Denture Protocol: How to produce a digital denture from start to finish

For more information, listen to our latest podcast on dentures with Jim McEachern

With over 50 years of experience as a Lab Technician, Keating Dental Lab’s very own Removable Department Manager, Jim McEachern, shares the incredible journey of his career with the Dental Up Podcast. Originally from Boston, Jim’s family moved to California when he was 4, and since then, he’s been around the world. For the most recent 18 years of his career, he has been with Keating Dental Lab, where he continues pursuing his passion in dentistry. In his spare time, Jim enjoys fishing and sailing. He’s been happily married for 47 years and has two sons. He especially enjoys his time with his cat Tucker!

In this episode of the Dental Up Podcast, you will hear about:

• How Jim got started in DentistryStudying with the Military

• His experience working with the World Renowned Dr. Niles F. Guichet

• Early days of the Removable Department

• The impact of CAD/CAM on Removables

• How Keating Dental Lab does Digital Dentures

We at Keating Dental Lab are always prepared and willing to help! Give Jim a call at (949) 955 – 2100 ext. 405 if you have any questions!

Discover us and subscribe on your favorite listening platforms like Spotify, Apple Podcasts, iHeart Radio, YouTube, and more!

Spotify: https://open.spotify.com/show/6gfHeYc6WHsPfzVdoLQVV9

iHeartRadio: https://www.iheart.com/podcast/263-dental-up-28030030/

YouTube: https://www.youtube.com/c/keatingdental

Written by Kyle Keating

Written by Kyle Keating

New Business Development

Keating Dental Lab

P: 1 (800) 433-9833

A: 16881 Hale Ave, Irvine, CA 92606

W: keatingdentallab.com E: kyle@keatingdentallab.com