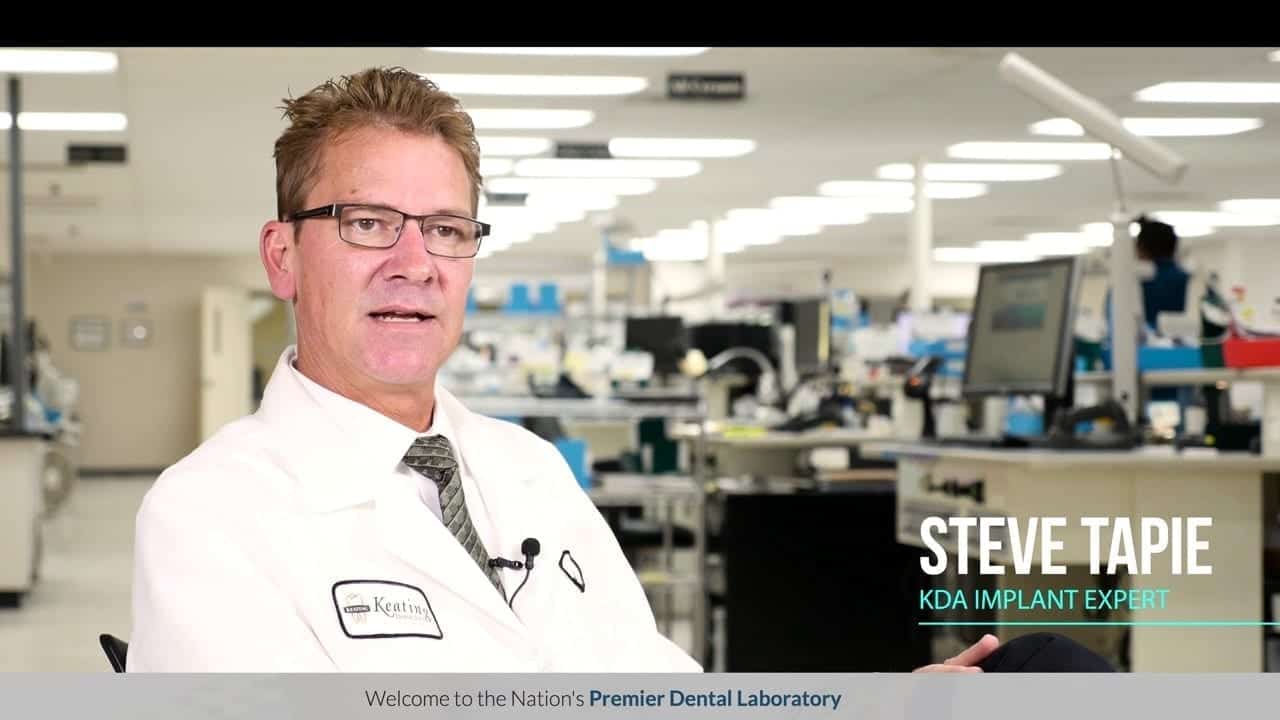

November 12 2015 — Dental implant expert “Steve Tapie” from Keating Dental Lab Digital Implant Lab department takes you through working with KDA Laboratory through the manufacturer abutment process with Atlantis by Dentsply. This remarkable Large Dental Lab in Irvine California offers a wide variety of custom manufacturer abutments as well as digital scanning for all dental implant systems. Take a walk throught things clinicians need to know when working with custom abutments and how to save a little money in the abutment to dental lab process. As per usual, this amazing dental implant video series is filmed and produced in full 4K ULTRA HD for your viewing pleasure and to get a better idea of the dental lab & staff.

Video Transcript with Stevie Tapie (Implant Expert):

Steve Tapie: We do have the Atlantis Scanner here which we can design and scan, whether it be a titanium, a gold-hue, and/or the zirconia abutment, here at Keating that we can actually scan the model that you send in, send us the impression, we do the model work. We’ll scan it, and we’ll design the abutment, and before the abutment gets sent to us, they send us the file, we’ll review the file and do a little bit of modifying it, if we don’t like the contour of the profile, the tissue height or we don’t like the angle of which the abutment’s leaning towards, we can modify it in certain degrees until it’s actually what we’re looking for, as far as the restorative abutment, and then the crown going on top of it, because it all starts with the abutment. [00:04:00]

After that, then we can do any kind of crown. With the Atlantis we like to do, like I said, it could be anything from the zirconium to the gold-hue to just the regular titanium, and so we like to basically approve every design, once we get the case in the lab, and then we can go from there and have a great restoration.

You’d also like to watch: Successful Implant Solutions